Today we’re comparing skid steers and track loaders to learn which one is the best option for your operation. Here’s a solid look at both of these workhorses, including how they’re different and what the advantages and disadvantages are for each type of equipment.

Skid Steer vs Track Loader

So, what’s the difference between these two types of equipment?

The skid steer, often referred to generically under the brand name of the initial brand that introduced it, has wheels that tend to work better on relatively flat, open sites and on hard surfaces, though some models, such as a Kubota skid steer with appropriate traction drive, can be used in areas that could be accessed by a truck or SUV, and tend to be both faster and less expensive.

By comparison, a compact track loader has a steel or rubber track on each side that spread out the weight of the equipment over a larger area, providing better traction and less impact on the soil beneath it, but tends to have a somewhat higher price tag and slower movement, though the cost is decreasing as the market expands.

Both of these equipment types do a wide range of jobs, from acting as a bale spike or forklift of sorts to loading to operating a wide range of pneumatic attachments such as backhoes, digging augers, limb saws, brush mowers, and much more. Though the attachments are usually the same – some models by the same manufacturer are even interchangeable – there are some other differences to consider.

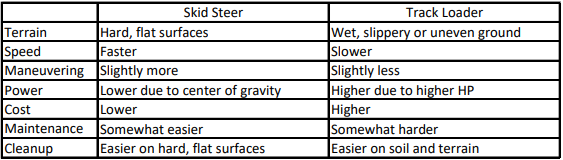

It’s very easy to consider the differences simply as track vs tire machines, but there’s more to it than that. The differences brought about by the traction and drive types can lead to other differences, which are covered in the table below.

The Skid Steer

New Holland skid steer in action.

How Does It Work?

For over six decades, the skid steer has been the Swiss Army knife of heavy equipment. Able to handle a wide range of tasks, it’s usually been the first option for many enterprises due to its do-it-all nature. They have tires, hydraulics, and a safe cab for an operator to work from and have a range of attachments that can be used. Common brands include John Deere, Case, and Catapiller, among others, but at Nelson, we’ve come to know and love the Kubota and New Holland models. This is because in being built by traditional tractor manufacturers, they tend to be built to hold up better to the pressures of agricultural use.

In a skid steer, hydraulics run the attachments and lifting mechanism, while the rest is operated under the engine directly. Because they operate on wheels, they’re a bit more limited than the terrain capabilities of a compact track loader, but they do operate a bit more quickly, which is important when you’re under a hard deadline.

Features, Advantages, and Use Cases

Unlike a tractor loader backhoe, a skid steer is able to get into very small areas due to its compact size. As an example, the smallest of the New Holland skid steer 300 models is under 6.5′ tall and a touch over 5′ wide. But that’s not the only advantage that skid steers have:

- Lower initial costs: Because they’ve been around for so long and have a simpler drive mechanism, skid steers are less expensive initially.

- Lower maintenance costs: It’s less expensive to repair or replace a tire than it is a track, and less has to come off for maintenance.

- Faster: Wheels move faster than tracks, so if time is of the essence, go with a skid steer to gain speed in your operation.

- More maneuverable: Though this is very close, skid steers are more maneuverable than track loaders, due to the ease of turning.

- Cleanup: On hard, flat surfaces, it’s much easier to clean up tire tracks than the tracks left by a track loader, though rubber tracks are closer.

For construction sites under a tight deadline, factories that have flat, hard surfaces, and other industrial applications where the skid steer can be operated on hard, flat surfaces, the skid steer provides faster operation and somewhat higher maneuverability at a lower initial and ongoing cost. However, the lowering market share shows that many companies are seeing the advantages of compact track loaders with rubber tracks over tire machines and are making the change to the newer option.

The Track Loader

Kubota SVL 65 track loader ready to get dirty.

How Does It Work?

The skid steer may have more history behind it, but the compact track loader has gained strong traction, if you’ll pardon the pun, over the past several years, especially with the addition of rubber tracks. The tracks provide a strong grip on the terrain, allowing the compact track loader to move safely and effectively across a wider range of slick, wet, soggy, or uneven terrain.

It has a lower center of gravity that allows it to translate more power into pushing and lifting things and is available in higher horsepower options than skid steers. The tracks also spread the weight of the machine across a larger surface area, making it easier for the track loader to “float” on boggy ground and prevent as much damage to the soil beneath it.

Features, Advantages, and Use Cases

Compact track loaders are still very maneuverable, and one would argue that they are just as maneuverable if it wasn’t for manufacturer recommendations to use 3-point turns to save wear on the tracks instead of turning in place. However, they have the same small size as a skid steer. Here are some other advantages to consider:

- Handles more terrain: Uneven terrain, rocks, smaller limbs – whatever the terrain, tracks make it possible to get over, around, or through it more easily.

- Doesn’t bog down: Because weight is distributed over more area, track loaders tread more lightly on the earth without getting stuck.

- Higher horsepower: Compact loaders are available in a range of higher horsepower than skid steers, which tend to top out around 85 HP.

- More power to work: Because the compact track loader has a lower center of gravity, it’s able to translate more power into the work it does.

- Cleanup: On soil, grass, and other soft surfaces, there is much less cleanup to content with using a compact track loader, because there’s less impact on the soil surface.

Unless you’re in a real hurry or only deal with flat, hard surfaces, a Kubota compact track loader or New Holland compact track loader with a rubber track system will provide a wide range of benefits. It delivers better performance in the same machine, similar maneuverability, though slightly decreased when used as per the manufacturer’s directions, better overall traction, and better float over boggy or damp ground. This makes it a better all-around machine for most purposes, and it’s one of the reasons we see so many more of these selling today than we do skid steer tire machines.

Conclusion

As you can see, there are a number of reasons why rubber-track track loaders are becoming more popular in the market, but Nelson Tractor knows that your operation is not one-size-fits-all, so we offer both types of equipment in a range of models to meet your needs. Whether you’re out on the farm, working at a carpet factory in Dalton, GA that’s getting out of forklifts, or are one of the many construction companies using track loaders in Georgia, Nelson Tractor has your back.

Further reading: see how the skid steer compares with the tractor loader backhoe here.

Contact us today and find out more about our outstanding line of Kubota and New Holland skid steers and compact track loader options.