Warning to our readers: Nelson Tractor Company’s blog posts are intended to give you tips on what works best from our opinion. We strongly recommend consulting on your owners’ manual as the ultimate guide.

The power take off (PTO) shaft is what powers implements that are attached to a tractor. The PTO shaft rotates at a much faster speed than human reaction time, so it is important to understand the parts and how to operate a PTO. It is also very important to not take any shortcuts when it comes to operating your tractor when the PTO is engaged. Even if it something you have operated many times, it is still necessary to be safe and take precautions in order to avoid dangerous situations, accidents, and injuries.

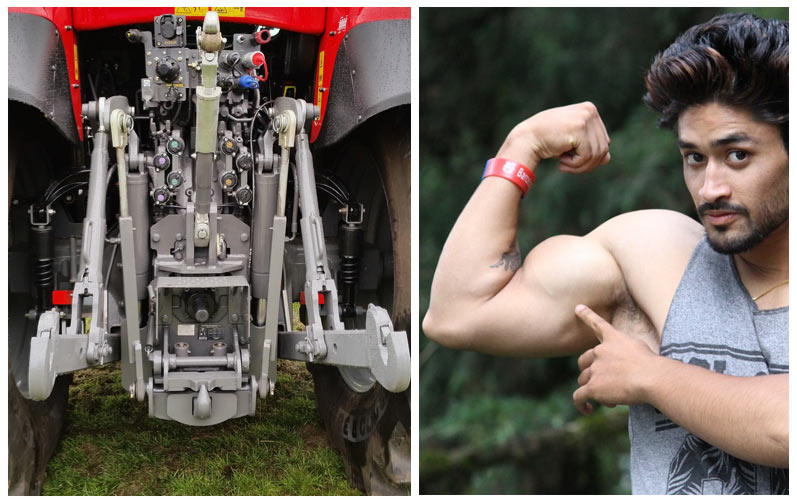

A tractor’s stub shaft, more commonly known as just the PTO shaft, transmits power from the tractor to the implement or the PTO driven machine attached to it. The transferring of power between the machines is achieved by connecting a drive shaft from the implement to the tractor’s PTO shaft. When operating at the full suggested speed, the PTO and drive shaft rotates at 540 rpm, which is 9 times per second, or at 1,000 rpm, or 16.6 times per second. The most obvious way to tell the difference in a 540 rpm PTO and a 1000 rpm PTO is to look at the splines on the tractor’s PTO shaft or the female connector part of the implements shaft. 1,000 rpm PTO shafts will have 21 splines where the 540 rpm PTO shaft will only have 6 splines. They rotate in proportion to the speed of the tractor’s engine at all speeds.

With that much power and speed, things are bound to happen. Here are the most common PTO shaft hazards and how to avoid them.

Entanglements

Usually when incidents occur involving PTO shafts, it is because people get too close to the rotating shaft or other moving parts. This danger is magnified when the person is wearing long or loose clothing. This can lead to dangerous and life threatening entanglements.

The PTO driveline is one of the oldest and most common farm equipment hazards. It is known as a mechanical wrap point hazard. This specifically refers to the part of the machine’s drive shaft that connects to the tractor. This drive shaft is identified as the implement input driveline, or IID, and is a wrap point hazard if it is not properly shielded. If the IID shaft is only partially guarded, the straight part of the shaft is usually covered, which leaves the universal joints, PTO connector (front connector) and the implement input connector (rear connector, also known as IIC), as the wrap point hazards.

Bolts and pins used as connection locking instruments are especially capable of snagging clothing. If clothing gets wrapped up and does not tear away from the body of the person, limbs can also end up wrapping. And even if body parts aren’t pulled into in the machine, limbs can become tightly compressed by clothing caught in the shaft and cut off the blood supply. The speed of rotation is so fast that a wrapping incident can occur much faster than a human can react.

Operator Carelessness

It is always best to stay securely in the seat of your tractor when operating the PTO; however, there are several reasons why a PTO may be engaged when no one is physically on the tractor. Some farm machinery powered by PTO is operated in a stationary position so an operator is only really necessary to start and stop the equipment. Elevators, or grain augers, for example. The operator starts and stops the machine, but can walk away and do other things. Other incidents are common when operators try to make adjustments or modifications while the machine is running. THIS IS EXTREMELY DANGEROUS AND HIGHLY DISCOURAGED!

Some work procedures, such as clearing a plugged machine can lead to an operator being exposed to a running PTO shaft or worse yet being pulled into a running machine. An operator should NEVER try to clear a plugged machine while the PTO is engaged. Other unsafe but common practices an operator should avoid include reaching for control levers from the back of the tractor, stepping across the shaft, mounting, dismounting, and having an extra rider on the machine when the PTO is running.

Projectiles

The wrap point hazard is not the only dangerous situation when it comes to IID shafts. Injuries have also occurred when shafts become separated while the tractor’s PTO is engaged. The IID shaft is one that slides into another piece, which is a feature that makes it much easier to hitch the tractor to the PTO powered machines. If an IID shaft is connected to the tractor’s PTO stub but no other connection is made between the tractor and machine, then it is possible the tractor will pull the IID shaft pieces apart. If this happens while the PTO is engaged, the shaft will uncontrollably swing and is likely to strike anyone who is in its range.

The swinging of the shaft can create a force strong enough to break a locking pin which will allow the shaft to become a flying projectile, or it may strike and break something attached to the rear end of the tractor. Separation incidents do not occur often, but when they do, the reason behind it is normally that the three-point hitch is not properly connected or aligned. That or the hitch between the tractor and the machine that is attached breaks or becomes unconnected.

Practicing PTO safety requires knowledge and training. Before you operate dangerous equipment of any kind, make sure you know exactly what you’re doing… and then practice what you know to stay safe.